horse feed bag printables

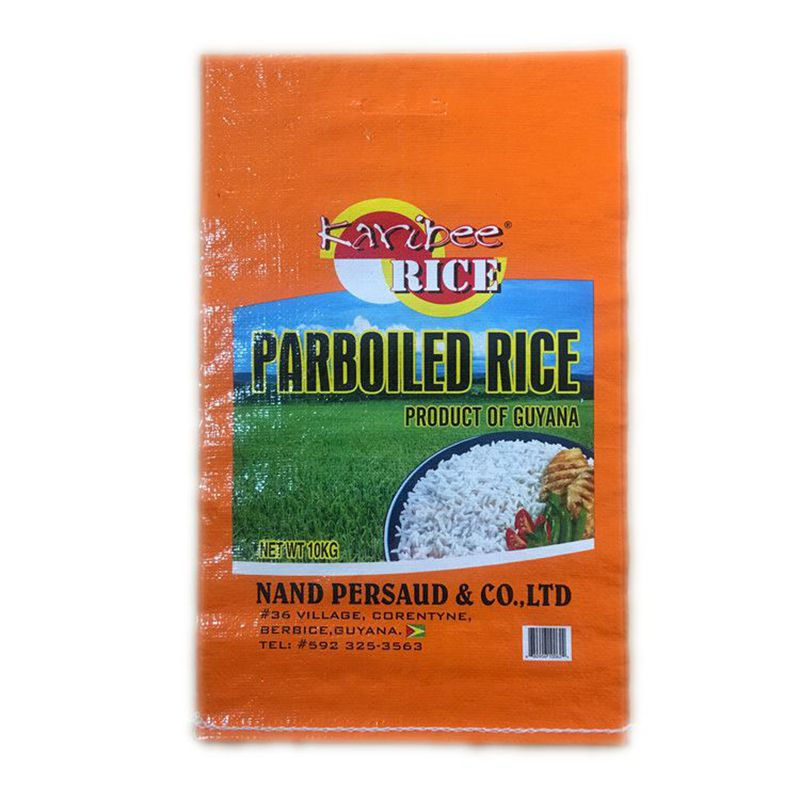

Bag Of Horse Feed with following specifications,

| RAWMATERIAL | PP |

| BOPP LAMINATED | YES |

| FABRIC THICKNESS | 58-95GSM |

| WIDTH | 30-72CM |

| 7 COLORS | |

| CUSTOMIZED | YES |

| SAMPLE | FREE |

| MOQ | 50000PCS |

| DELIVERY TIME | 10-15DAYS |

| PRODUCTION CAPACITY | 100000PCS PER DAY |

| PACKAGING DETAILS | BALE |

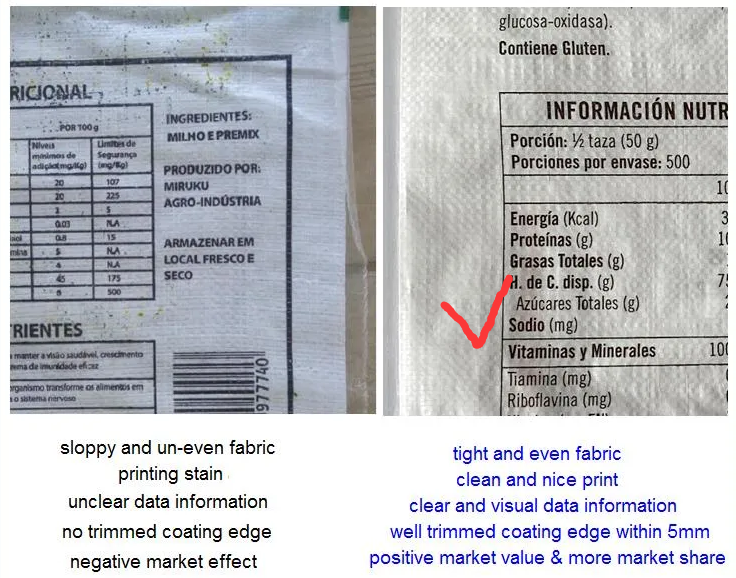

Horse Grain Bag is well recognize for their Performance, Strict quality parameters are maintained to avoid spillage, leakage Etc.

Equine nutrition Bag, Pet food Bag, Pig farming Bag, Poultry feed Bag, Sheep husbandry Bag,Sheep Goat Feed Bag,

Broiler Feed Bag.This Bags are used for packing Cattle feed Bag, Horse Food Bag, Dog food Bag, Bird food Bag, Cat food Bag,

Standardized food grade materials are using. Different sizes are supplying as per customer’s requirement.

25,50 Kg. Printed Cattle Feed & Animal Feed Bag, can be easily carried, it is re-used for shopping and indirectly the brand is promoted,

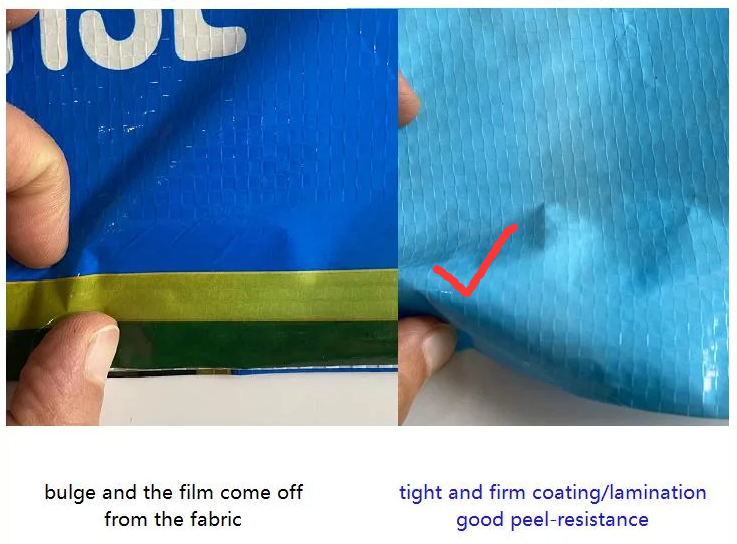

BOPP (bi-oriented polypropylene) bags stand out as the first choice for many industries.

Known for their durability, versatility and cost-effectiveness, BOPP bags are the first choice for businesses

looking to streamline their packaging processes while maintaining product integrity.

Whether you are in agriculture, pet food, or industry, BOPP bags are a reliable choice for all your packaging needs.

One of the main advantages of BOPP bags is their high tensile strength, which makes them ideal for packaging

heavy-duty products such as feed, seeds, chemicals and other industrial materials.

50kg BOPP bags are a popular choice for industries that require a strong and reliable packaging solution for bulk products.

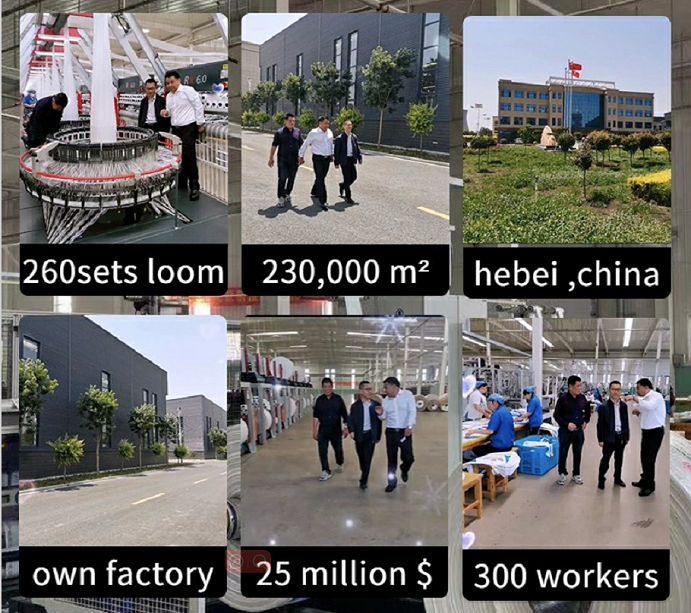

INTRODUCTION OF OUR FACTORY:

we have 3 our own factories in total:

(1)first factory located in Shijiazhuang , the capital city of Hebei Province.

It occupies over 30,000 square meters and more than 300 employees working there.

(2)the second factory located in Xingtang , the outskirt of Shijiazhuang city.

PP woven bags are a popular choice for packaging a variety of goods due to their durability and versatility.

Another important aspect of daily inspection is checking bags for signs of contamination or foreign matter.

Regardless of the method used, PP woven bags provide excellent packaging solutions for a variety of products.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags